Home (en)

Welcome to the home page

Unleash the power of innovation with FORJIN!

We are FORJIN

FORJIN is a business unit created in 2008, owned by Herragro S.A. Its purpose is to support the industry in the design and manufacture of forged, rolled and stamped steel products.

We are a Latin American benchmark committed to delivering high quality products.

We are FORJIN

FORJIN is a business unit created in 2008, owned by Herragro S.A. Its purpose is to support the industry in the design and manufacture of forged, rolled and stamped steel products.

We are a Latin American benchmark committed to delivering high quality products.

Integrated management system

- Quality management system certified under ISO 9001 Version 2015.

- Processes aligned with ISO 14001 and 18001 standards.

- Product conformity in manufacturing and marketing (control plans, SPC).

- Measurement systems (MSA)

Integrated management system

- Quality management system certified under ISO 9001 Version 2015.

- Processes aligned with ISO 14001 and 18001 standards.

- Product conformity in manufacturing and marketing (control plans, SPC).

- Measurement systems (MSA)

MILITARY INDUSTRY

Herragro currently supplies the totality of forged parts for the Colombian military industry, delivering:

- Special alloys

- High reliability and durability

- Precision forging: less machining

- Structural and metallurgical integrity

- Heat treatments

KENWORTH ENGINE MOUNT

SMALL SUPPORT

- Manufactured in high carbon steel SAE 1045.

- One-piece hot forging.

CHEMISTRY

- According to the diameter of each ball, our solid quality system controls the supply of raw material in order to optimize its microstructure.

- home.experience.balls.c2.list.1

KINGPIN

WHY PREFER A FORGED KINGPIN?

- Because it is the only one in Colombia manufactured under the forging process, in addition to its hardness, tensile strength and torque resistance.

- This texture shows its heat treatment, which guarantees quality and safety.

- Steel type: SAE 4340

- Manufacturing process: Hot forging

- Heat Treatment: If applicable

- Hardness (Rockwell C): 35 - 42

- Tensile strength (Ton): 120

- Torsional strength (Ton): 68

FORGED STEEL BALLS

SIZES

- Adjusted to the measurements required in each process from 1“ to 6”

CHEMISTRY

- According to the diameter of each ball, our solid quality system controls the supply of raw material in order to optimize its microstructure.

Surface and volumetric hardness

- We develop the microstructure through heat treatments.

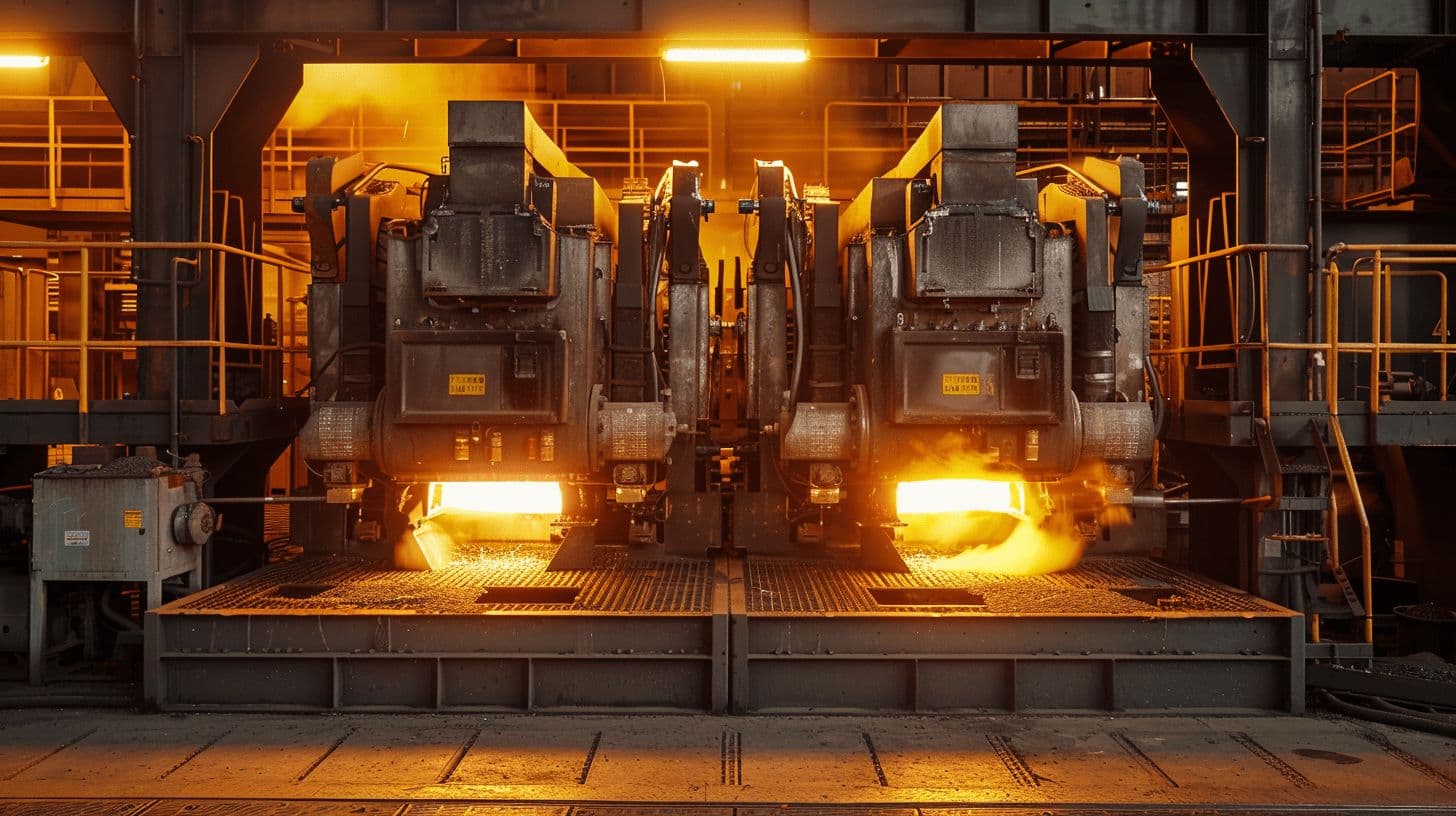

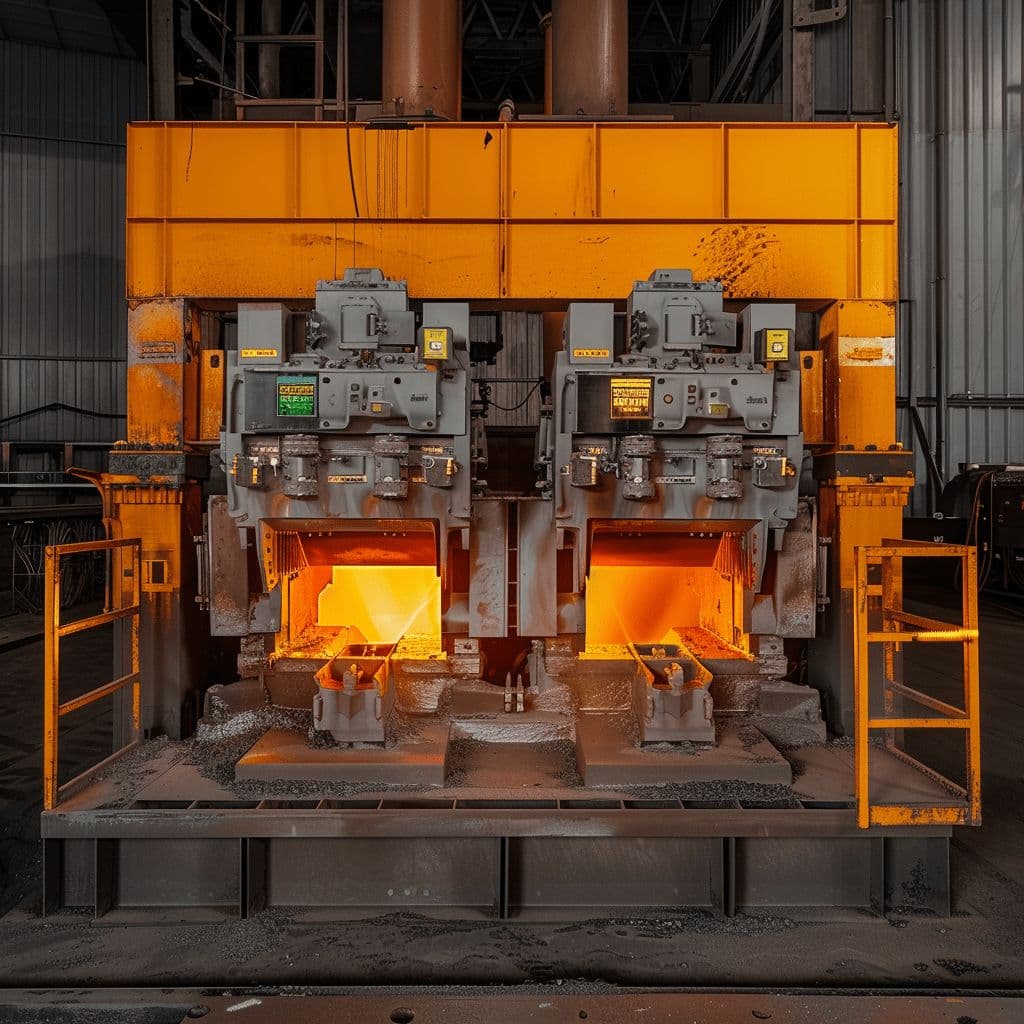

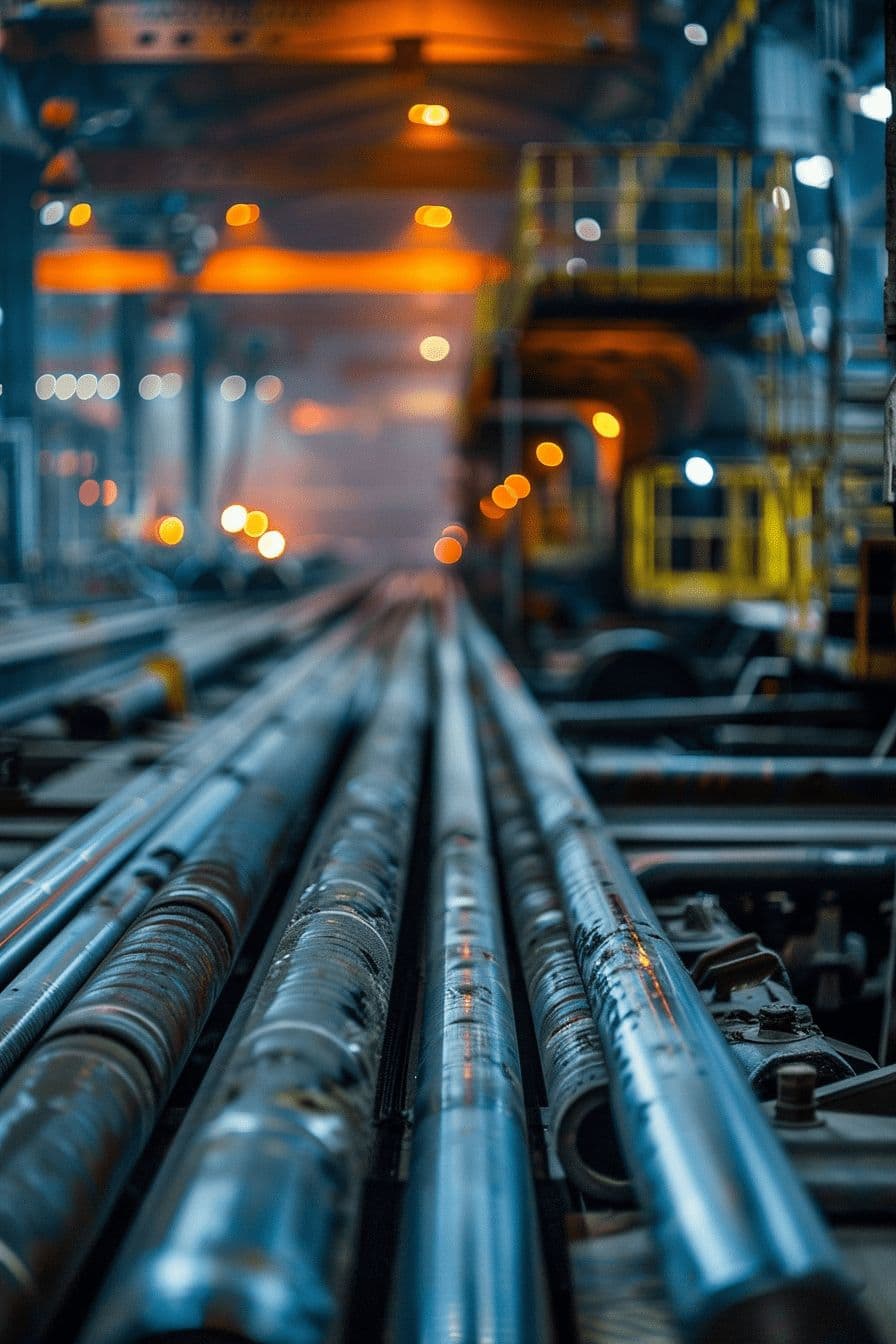

ROLLING MILL

We have a State-of-the-art rolling mill (automatic self-reversing duo and induction furnace) to process the raw material for all our forged products, which gives us an advantage over other companies.

ROLLING MILL

We have a State-of-the-art rolling mill (automatic self-reversing duo and induction furnace) to process the raw material for all our forged products, which gives us an advantage over other companies.